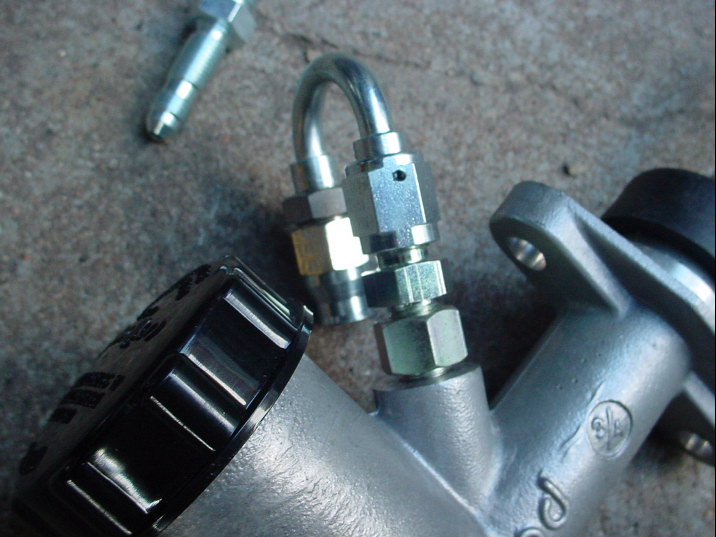

The deal with the wilwood "small brake/clutch" m/c is that it has a -3 AN female outlet, but it is too deep for a normal -3 male-male union. So the m/c comes with this adapter, which comes out as a 3/8"-24 female inverted flare fitting.

Also, my HTOB came with -4 fittings and line. So I bought a union that was 3/8"-24 male inverted flare to -4 AN. Problem is that this is cumbersome, ugly, and it would hit the firewall. See pic:

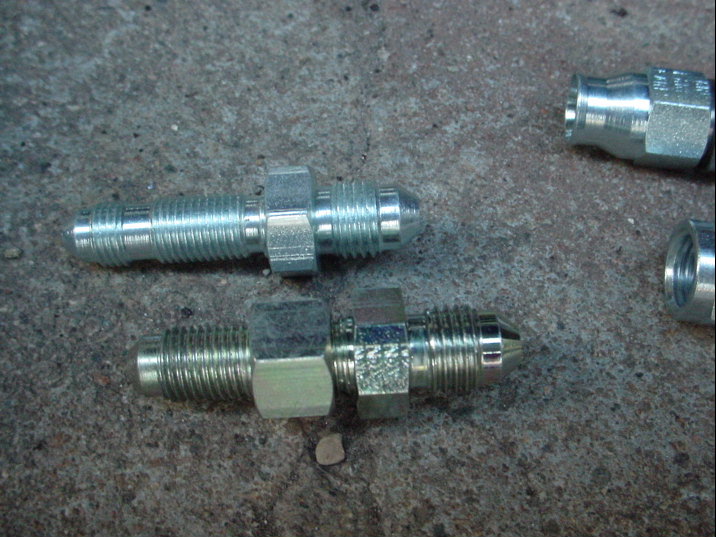

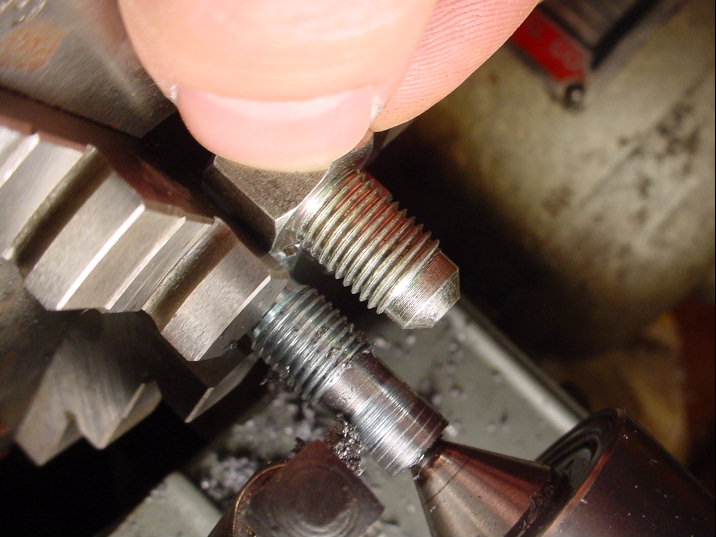

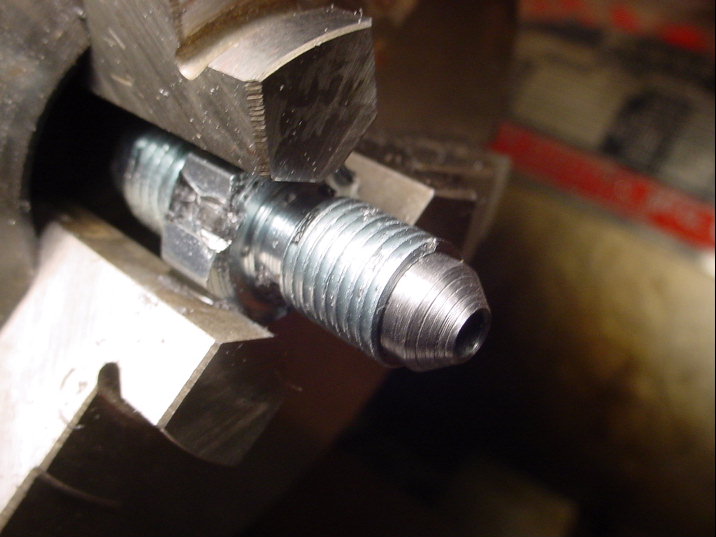

Another problem, the adapter that the m/c comes with is really a -3 long, to reach the deep hole. No one sells -3 long to -4 unions. Earl's does make a -3 to -4 bulkhead fitting, so I got one of those, and machined it down so that it was the same depth as the wilwood fitting. It works great.

The bottom part is the wilwood piece to the 3/8-24 to -4 union. See how much longer it would be.

Machining. Oh yeah, the wilwood fitting has what seems to be a 45° angle on the tip. I put a normal 37° on mine. Seals fine. It does appear that the angle in the m/c itself is actually 45°.

Tilton hydraulic throw out bearing on a T-5 transmission. (This is for my V8 240)

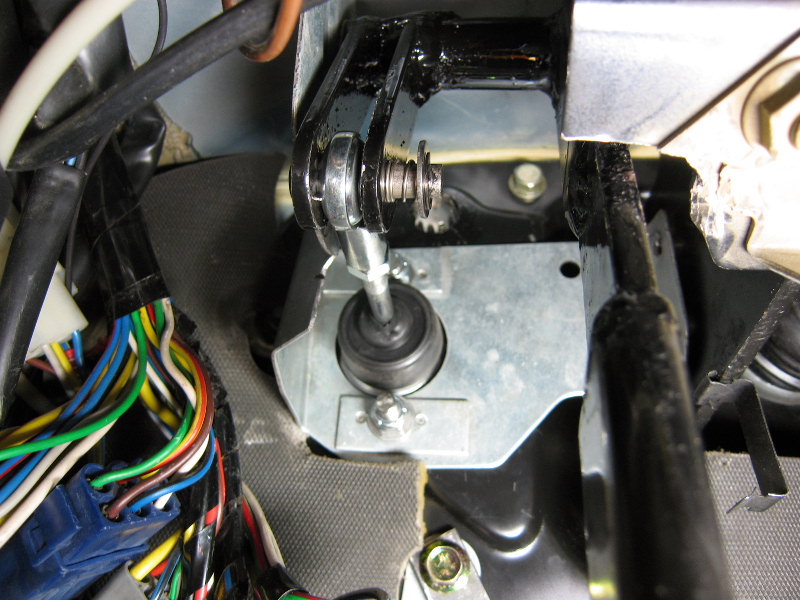

Under the dash. The spring is there temporarily because the clevis pin was too long. Also had to drill the 3 holes through the firewall because my car is a 90. Also trimmed the bracket where the pedal is touching, in the upper right of the pic. Turns out that it wasn't necessary, as the pedal stroke isn't that long, so now the pedal is closer to the firewall.

You need to make a pedal stop for the HTOB. I wasn't too crazy about drilling yet another hole, so I used an existing hole to mount the stop.

I started with the .750 bore, but it was too stiff. I have the .700 now, and it is very nice. Pedal stroke is still quite short, so I think I could go to the .625 bore to get even less effort, and it should still move enough fluid. With .625 bore, the clutch effort would probably be Honduh easy.

A picture of the modified 240 cable clutch pedal. The pedal is lengthened, and the connection point to the m/c is below the pivot point. The cable attachment point was above the pivot point. The pivot point itself is higher in the pedal box when you are using the hydraulic setup.