Making the

"Pinhole Drill"

Instead of having a glass lens like

"normal" cameras, the pinhole camera uses a tiny hole, a needle-sized hole, to

form the picture inside the camera. The best size of pinhole for this camera body is one

which is 1/100th of an inch in diameter. There is a fine needle which is that size--the

#16 beading needle. Because the needle is small and difficult to handle, it must be glued

into a handle to make a "pinhole drill." As illustrated below, the drill is easy

to make, and once prepared, it can be used to make hundreds of pinholes in the soft

aluminum stock cut from soft drink cans.

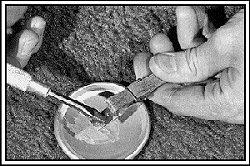

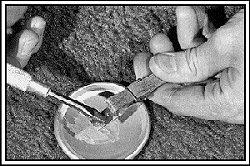

Mix

the epoxy in the cut-off end cap of a soft drink can. Place epoxy in the mouth of the

clothspin and insert the needle until it protrudes about 1/4 inch. You may have to cut the

back of the needle off to make it fit into the clothspin. If the needle protrudes more

than about a quarter inch, it will easily break off when used to drill pinholes.

Mix

the epoxy in the cut-off end cap of a soft drink can. Place epoxy in the mouth of the

clothspin and insert the needle until it protrudes about 1/4 inch. You may have to cut the

back of the needle off to make it fit into the clothspin. If the needle protrudes more

than about a quarter inch, it will easily break off when used to drill pinholes.

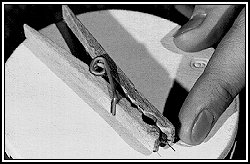

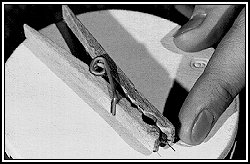

The

finished "pinhole drill" should look like this: notice the 1/4 inch length of

the drill shaft.

The

finished "pinhole drill" should look like this: notice the 1/4 inch length of

the drill shaft.

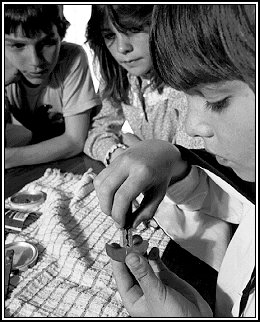

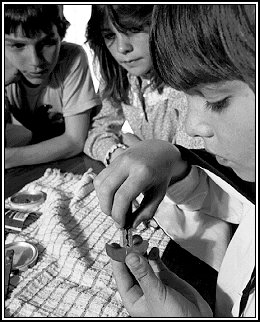

Here you see the delicate task of

drilling a pinhole in the aluminum plate. This is an important part of making a pinhole

camera. It requires a delicate touch and a bit of patience. A fine pinhole will result in

sharp photographs and will last for centuries! Following are the steps for using the

"pinhole drill" to make a fine-quality pinhole lens.

Back - Home - Next

Mix

the epoxy in the cut-off end cap of a soft drink can. Place epoxy in the mouth of the

clothspin and insert the needle until it protrudes about 1/4 inch. You may have to cut the

back of the needle off to make it fit into the clothspin. If the needle protrudes more

than about a quarter inch, it will easily break off when used to drill pinholes.

Mix

the epoxy in the cut-off end cap of a soft drink can. Place epoxy in the mouth of the

clothspin and insert the needle until it protrudes about 1/4 inch. You may have to cut the

back of the needle off to make it fit into the clothspin. If the needle protrudes more

than about a quarter inch, it will easily break off when used to drill pinholes. The

finished "pinhole drill" should look like this: notice the 1/4 inch length of

the drill shaft.

The

finished "pinhole drill" should look like this: notice the 1/4 inch length of

the drill shaft.